Surface Control

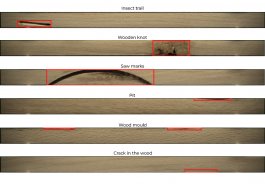

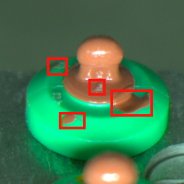

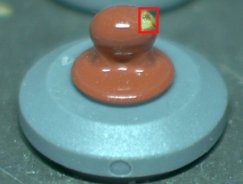

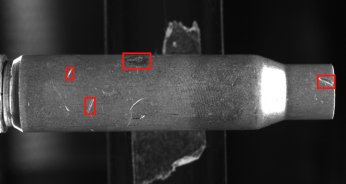

We find the smallest deviations in material surface quality

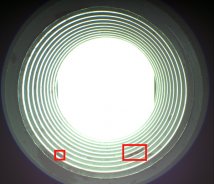

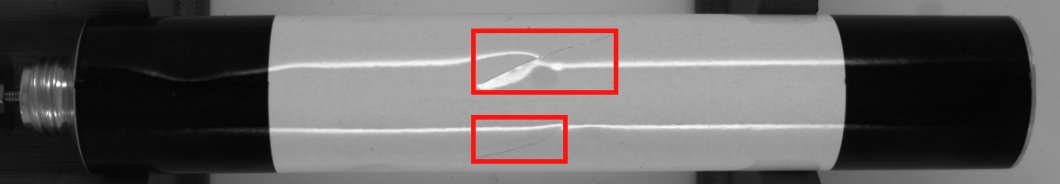

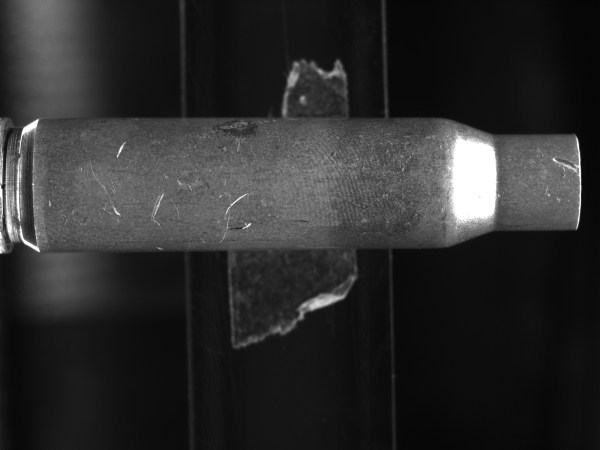

Thanks to the unique connection of the latest technologies, we can do a 360° control of product surface at a speed of up to 800 pieces/min. During the control, we use the principles of artificial intelligence and advanced methods of object scanning, which are processed by a unique set of our own machine vision libraries. We can identify abrasions, scratches, falls, burrs and other defects on the entire surface of the product, regardless of the material used.

Which products can be optically controlled?

- large planar surfaces

- drawn material - wires, strings, tubes

- slats and other smaller products that can be placed on the conveyor

- wooden products

- plastic moulded products

- turned parts

- threads

Leave the stereotype and challenging tasks to the machines, people can do more meaningful work

| Human NO! | Optical control system Yeah!!! |

|---|---|

|

Control max tens of pieces/min |

Controls up to 1000 pieces/min |

|

Tendency to change the opinion on product classification over time |

100% evaluation objectivity |

| Susceptibility to concentration loss of due to external influences | 100% concentration |

| Suffers from fatigue | Always works with the same alert |

| Needs breaks, vacation ... | Works constantly |

| Needs constant training and refreshers in case of changes | In case of changes, just needs a modification of a few parameters |

| Manually reports defect statistics from production | Automated reporting that is always correct and accurate |

Automation options and industry 4.0

KINALI optical control systems provide data connection to any superior ERP or MES system. Our cameras respond precisely in the spirit of Industry 4.0 to the stimuli of other production nodes, can provide the results of their controls, provide statistics or automatically back up data.

The scalability of individual production nodes and their mutual connectivity brings higher efficiency and objective data from production. The advent of Industry 4.0 is becoming commonplace around the world. Those who get a head start in digitisation will be more competitive in globalised modern industry.

BENEFITS OF QUALITY CONTRO AUTOMATION

Financial savings

Have you calculated how much you spend on complaints per year? From now on, you can throw all your worries away.

Customer reputation

Your customers will always speak well of you.

Higher control efficiency

Surface control in the order of milliseconds compared to lengthy manual control.

Identical products

Quality control automation ensures unifying defect evaluation metrics.

MENU

MENU