Logistics is a dynamic industry where customers‘ need for speed and accuracy of delivery is constantly increasing. A perfect example of the trend of instant delivery is the Czech e-shop Alza, with its motto, "Order by midnight - have it in the morning in AlzaBox." This approach not only sets a high bar for competitors but also changes customer expectations. Waiting periods are no longer calculated in days but in hours.

To keep up, companies need to increase productivity and eliminate errors. This cannot be achieved without automation. Modern warehouse automation allows for continuous operation without the need to increase staff or pay extra for shifts at night or on weekends.

The Test-it-off platform is the answer to the challenges of modern logistics

Test-it-off is a universal robotic platform that connects all the key elements of modern automation – from sensors and bin picking or collaborative robots to integration with a warehouse system (WMS). It is designed to adapt to the needs of a specific operation while remaining easily scalable. In the next section, we'll show how the platform works, how its logistics arm came about, and what specific benefits the deployment of myFABER® Test-it-off Cobot, which was created in cooperation with the KVADOS GROUP, brings.

How the Solution’s Building Blocks Fit Together

The Test-it-off platform is a universal software core for industrial automation. Its offshoot Test-it-off for Logistics, applies the benefits of this platform to order picking processes in automated warehouses. This specialised application has been developed in collaboration with the KVADOS GROUP into the myFABER® Test-it-off Cobot, which offers a fast and modular solution for the entire order completion process.

Test-it-off: universal automation software platform

The Test-it-off platform was developed by the Brno-based company KINALI with the aim of simplifying industrial automation and making it accessible to workers without technical knowledge. It allows you to connect a variety of hardware and software into one system and control everything from an intuitive interface.

An example of successful deployment is the cooperation with BTL Medical Technologies s.r.o., where Test-it-off helped solve the shortage of skilled workers by automating the testing of printed circuit boards.

Test-it-off for Logistics: Specialization for Warehouses

Test-it-off for Logistics expands the basic platform with tools and modules optimized for logistics. It focuses on order picking automation, combining intelligent item recognition, handling, and reporting to make processes faster, more accurate, and easily scalable.

myFABER® Test-it-off Cobot: the smart picking system

In cooperation with the KVADOS GROUP, the practical and flexible myFABER® Test-it-off Cobot solution was created, which is based on the specialized Test-it-off for Logistics platform. This device expands the myFABER® portfolio with fully automated picking for shipment preparation, which easily connects to existing WMS and other automated warehouse handlers in the myFABER® ecosystem.

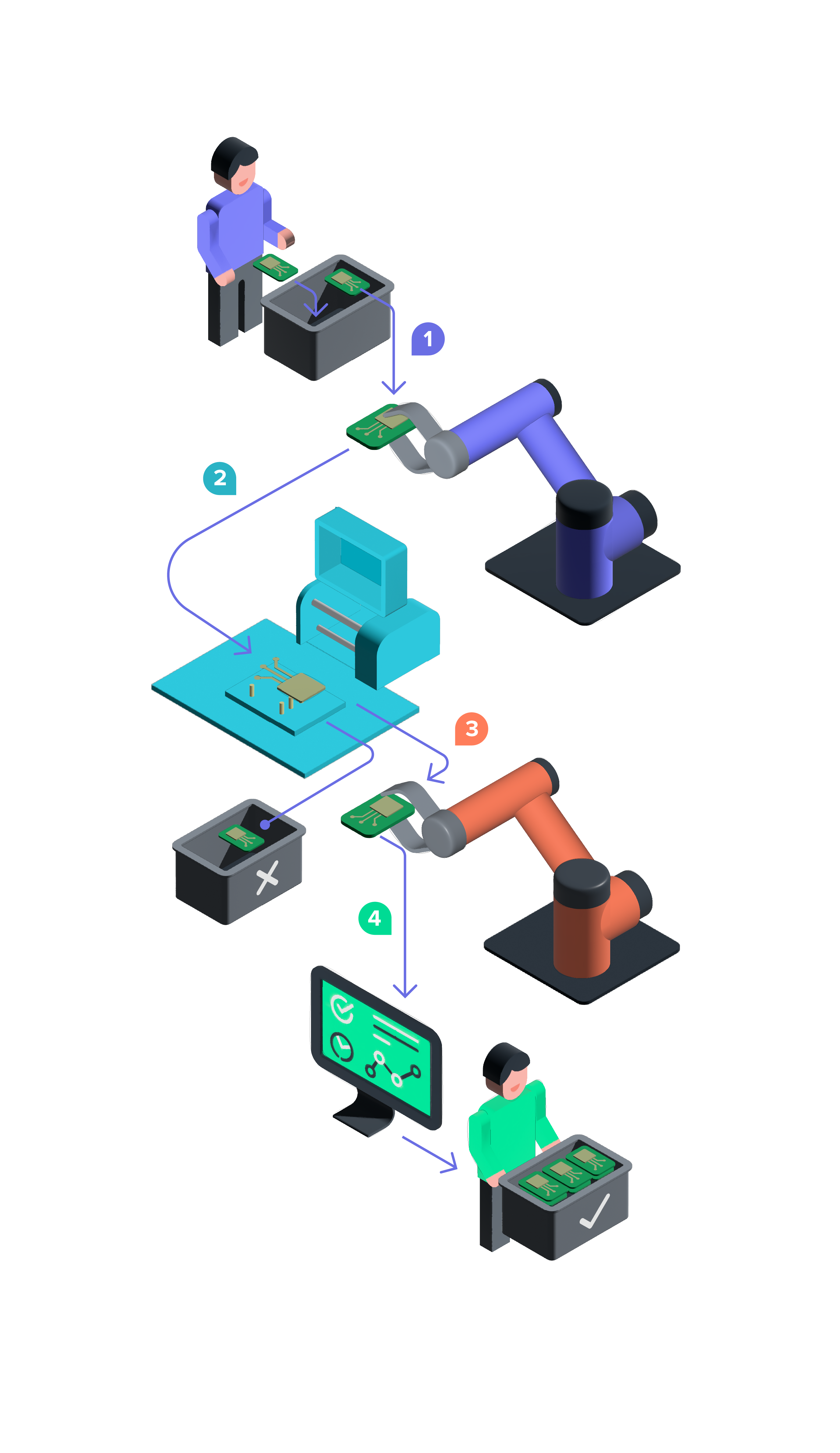

The solution covers the entire process, from precise localization of products in warehouse storage using 3D bin picking technology, to the physical completion of the order in the final shipping package. It helps to eliminate one of the last manual tasks in warehouse logistics. The result is an efficient and scalable solution that makes the entire picking process faster, cheaper, and more accurate.

A key advantage of the system is its ability to handle products of different sizes and shapes, allowing it to be used across a wide range of industries. It also requires minimal space. In many cases, it takes up less room than a typical picker.

Key Features and Technologies of myFABER® Test-it-off Cobot

The company KINALI has integrated three main technological elements into the solution:

| Proprietary 3D bin picking system | Provides identification and handling of unsorted products in KLT boxes or other packaging types. |

| AUBO collaborative robots | Cobots capable of handling products weighing up to 20 kg, designed for safe and reliable use in automated warehouses. |

| Proprietary Test-it-off software | Control software that allows easy management and orchestration of hardware elements at the workstation, advanced reporting, and integration with WMS. |

Is It Worth Automating Order Picking?

| Minimized Errors | Advanced algorithms and artificial intelligence reduce the risk of order picking errors, such as mix-ups or missing items. |

| Continuous Operation | The system can operate 24/7 without the need to manage shifts, holidays, sick leave, or staff turnover. |

| Efficient Use of Resources | Routine and repetitive tasks are handled by technology, allowing human workers to focus on higher-value-added activities. This results in significant cost savings and minimizes the reliance on manual labor. |

| Scalability | Thanks to its modular design, the system quickly adapts to new requirements without the need to recruit additional employees. |

Although the initial investment in automation may be higher than hiring staff, these long-term benefits far outweigh the cost.

Prospects for future development

Automation in logistics not only addresses current challenges, such as reducing logistics costs and meeting shorter delivery times, but also lays the foundation for future development and innovation. Solutions such as the myFABER® Test-it-off Cobot support the advancement of Industry 4.0 principles and promote greater flexibility and sustainability across logistics chains.

Conclusion

Automating picking with myFABER® Test-it-off Cobot proves that the combination of artificial intelligence, robotics and smart software can fundamentally transform logistics operations. The result is higher efficiency, lower operating costs and increased customer satisfaction. You can find out more on the Test-it-off for Logistics website or on the myFABER® Test-it-off Cobot product page. You can also experience the system in action at the myFABER® showroom in Paskov near Ostrava. Book your showroom visit today!

MENU

MENU