Get smooth production with robotic systems

Work robotisation will bring you a faster production pace and greater flexibility in the introduction of new products or in the event of supply outages. We can also handle the automation and digitisation of older functional units, so you don't have to change the entire system.

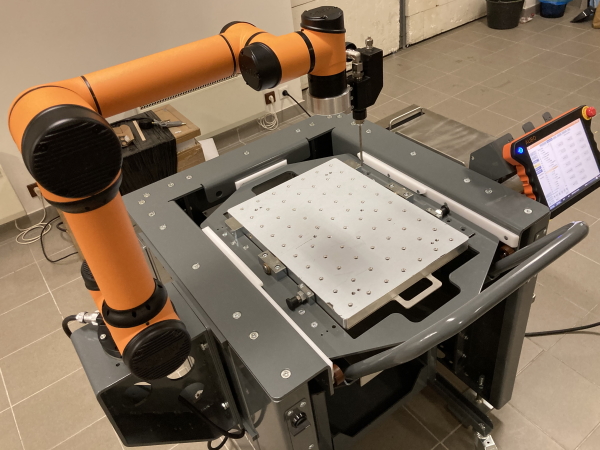

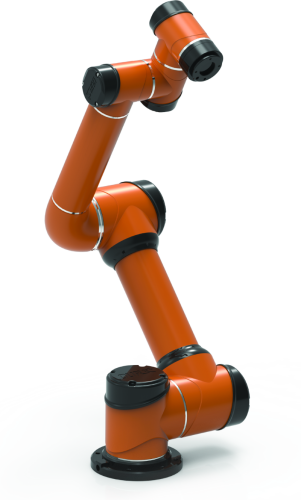

We have years of experience with the construction of robotic systems. The common denominator of all our solutions is the collaborative robot AUBO, which we can deploy on a wide range of production automation applications. AUBO cobot is perfect for automated machine operation, automated welding or assembly. However, we can also equip our AUBO cobots with cameras and artificial intelligence. In addition, our software tools can even handle the most demanding external connectivity requirements easily. And you can start functioning immediately according to the principles of Industry 4.0.

We will assemble the robotic system customised to your operation. You will gain higher efficiency and secure long-term competitiveness and market position.

ROBOTIC SYSTEMS KINALI CAN EASILY DO, FOR INSTANCE,…

TECHNOLOGY WE USE

Industry 4.0

Automation, robotics and communication between production nodes. With the principles of Industry 4.0, you will always be one step ahead.

Single-purpose machines

Specific tasks are a piece of cake for specialised machines. We prepare them so that they outmatch all masters of their domains.

Collaborative robots

Universal and flexible hard worker that works 24/7. It interacts safely with human colleagues and makes no mistakes at work.

MENU

MENU